| Wafer Laser Marking System |

| PCP-LM8 |

<Option Feature> Significantly shorten the Takt Time by SLM Mode |

SLM stands for Stored Layout Marking that is the data processing mode we

developed to reduce Takt Time.

This mode uses the built-in memory in laser controller to speed up the marking process. (※1)

It is expected to reduce the Takt Time by approx. 30%(※2) compared to PCP-LM8 standard mode and 50% (※2) compared to PCP-105LM.

※1 Condition: Scaling OFF and matrix marking mode (same marking in the Lot).

※2 According to our research: Takt will change depending on the number of wafers in the Lot, marking condition, prober settings, etc. |

| Clear Color and Damage-free by UV Wavelength |

Compared to the fundamental wavelength (1,064 nm), the UV wavelength (355

nm) has a much higher absorption rate into the material, and highly visible

marking is possible.

Since heat stress is not applied to the product, damage can be reduced. |

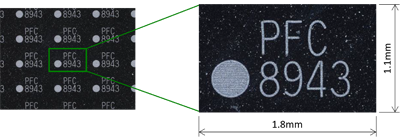

| Sample A(Device without BG) |

・Font size

・Solid circle

・Letter

spacing

・Print depth |

:

:

:

: |

0.3mm×0.15mm

φ0.3mm

0.05mm

2.2μm |

|

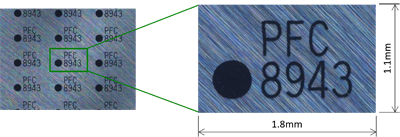

・Font size

・Solid circle

・Letter

spacing |

:

:

:

|

0.3mm×0.15mm

φ0.3mm

0.05mm

|

|

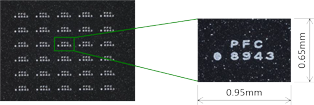

| Fine Marking with Very Small Spot |

| Since the UV wavelength (355 nm) is 1/3 of the fundamental wavelength (1,064

nm), the spot size can be narrowed down by that extent, and it is possible

to print in extremely small letters in a limited space. |

| Print at Smallest Printable Size |

・Font size

・Solid circle

・Letter

spacing

・Print depth |

:

:

:

: |

0.08mm×0.08mm

φ0.08mm

0.05mm

2.6μm |

|

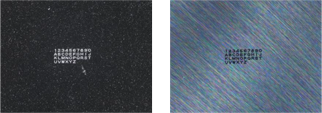

| Print 36 Alphanumeric Characters at 0.1mm Square |

・Font size

・Letter

spacing

・Print depth |

:

:

:

|

0.1mm×0.1mm

0.05mm

1.6μm

|

|

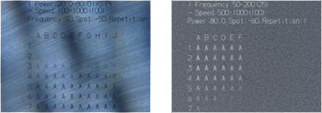

The sample marking function can mark a matrix form sample changed from the marking parameters.

Different marking parameters can be assigned for the vertical and horizontal axes of matrix.

| 【Example】 |

[Vertical axis] Laser power 20% to 80% |

|

[Horizontal axis] Scan speed 200mm/s to 500mm/s |

By evaluating the sample marking results marked by changing the marking

parameters in stages, the optimal combination of marking conditions can

be found in a short time. |

| Predictive Maintenance Function |

Power Monitor is equipped standard in Laser Head.

It realize the management of "Laser Power" that is most important for a laser equipment easily and reliably. |

The functions mounted on the prober are inherited from the previous model

(PCP-105LM).

Ensures stable productivity. |

・Supports 6-inch wafer and 8-inch wafer

・Original wafer chucking method

・High-precision alignment

・Split marking, individual marking |

|